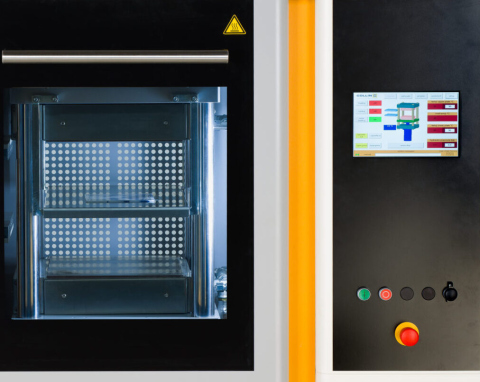

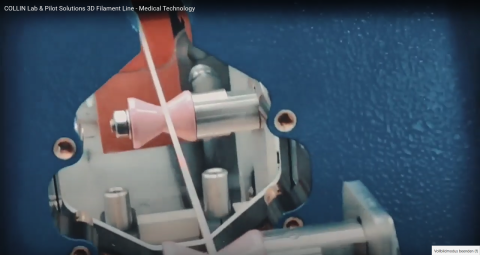

They are manufactured according to the guidelines of the FDA 21 CFR, ISPE, ISO 13485, DIN EN 10204/3.1B, cGMP/GMP.

Advantages

- Highest precision

- Tight tolerances

- Cleanness

- Process accuracy

- Good cleaning handling

- Clean room conformity

- Quick and excellent service

- Custom-designed

- Customer training programs

Exemplary applications

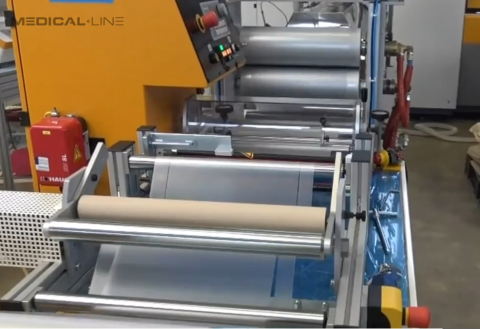

- Clean-room technology – design for the production of medical or pharmaceutical products

- Quality control of materials

- Production of test sheets/samples

Customers

- Universities and institutes

- Pharmaceutical companies

- Medical technology companie