K 2019: COLLIN Module line – high precision for sustainability

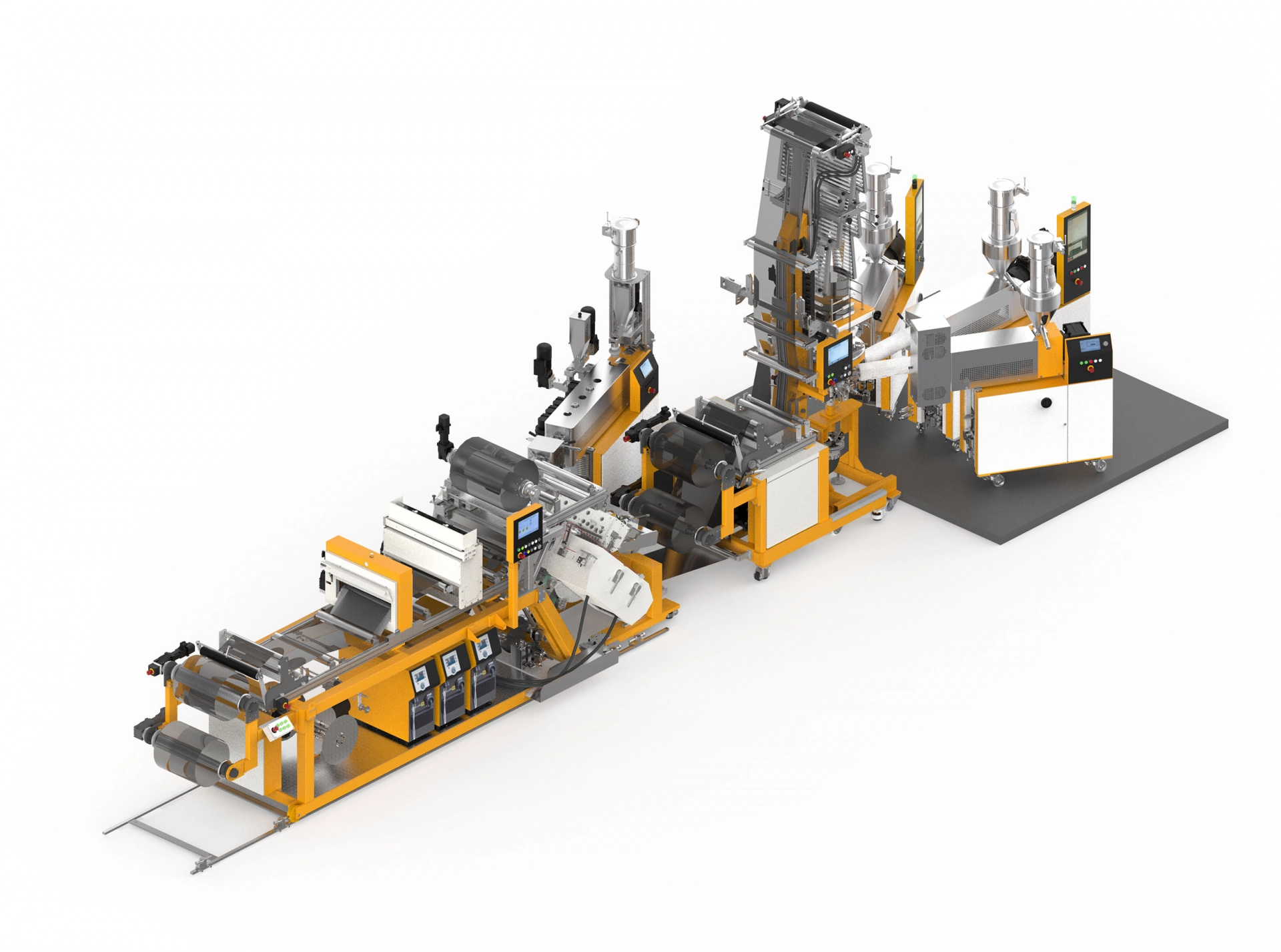

Highlight at the COLLIN booth is the blown film line combined with the 600 mm calender as inline system for extrusion coating:

Highlight at the COLLIN booth is the blown film line combined with the 600 mm calender as inline system for extrusion coating:

„These actually independent systems for blown film and flat film production are interconnected inline and thus, new film systems are possible. Especially in these times, where packaging has to be re-thought in order to support the environmental aspect and to improve the recyclability, these lines enable new product ideas to create packaging in a more sustainable way without abandoning the performance of modern multi-layer film systems, explains DI Dr. Friedrich Kastner, CEO / Managing Partner COLLIN Lab & Pilot Solutions GmbH. The Collin line at the booth includes numerous new modules and features.

„The main advantage is, that with this line, we can produce films with highly precise layers. The layer distribution is made for example by radial mandrel distributors calculated with CFD support. In this way, we optimize the layer structure and thickness to a level that is unique. With this line, COLLIN exceeds the sustainability requirements of our time!” says Kastner luckily. Because with the COLLIN development, the film layers can be designed in a very thin way – with this, the extrusion specialist allows for new, better packaging and technical films as solutions for tomorrow.

For standard & bio polymers, post-industrial & post-consumer material

„With this line, our customers are in a position to process standard polymers but also bio polymers as well as post-industrial and post-consumer materials – on the highest precision level”, explains Corné Verstraten, CSO / Joint Partner COLLIN Lab & Pilot Solutions GmbH.

The three COLLIN extruders of the blown film line have been equipped with new adapter systems. The blown film line itself is a consequent further development of the COLLIN lines and is equipped with many new details, e. g. new calibration basket, the new take-off unit as well as a new winder. With an integrated inline viscosimeter and the Collin FI camera system, the product quality is constantly controlled, which is essential, especially if recycled material in sensitive areas such as packaging is used.

At the end of the line, the COLLIN team combines two winders – a 600 E gap and an auxiliary winder in order to guarantee continuous production.

COLLIN Module line

Blown Film Unit BL 600 P with camera inspection

Extruder E 25 P

Extruder E 30 P

Extruder E 25 E

4-Layer Blown Film Die RW 40 with melt splitter

Extrusion Coating 600:

Compounder ZK 25 E x 48 D combined with a melt pump

Slot Die BSD 500

Calender CL 168/250/250-600 P with Winder W 600 E gap

Media contact resp. for foto files, please contact: Dr. Isabella Pichler,

isabella.pichler@collin-solutions.com