The manual COLLIN pressure filter test is used for determining quality differences in a polymer caused by agglomerates, insufficiently dispersed fillers resp. contaminations.

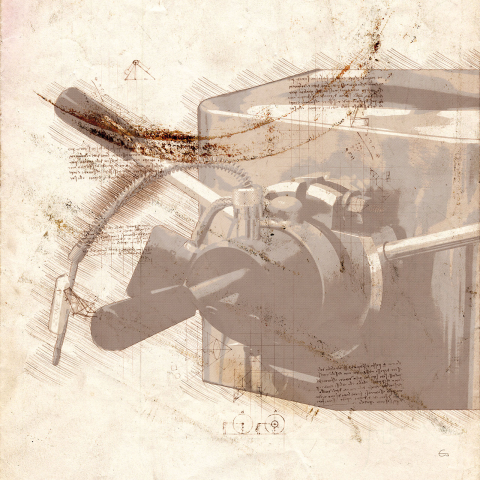

A filter cassette in pre-heating position enables a quick and clean manual filter change without extruder stop. During the filter change, the melt is diverted via a bypass valve in front of the filter.

The material to be tested is melted in an extruder, homogenized and guided through a screen via a melt pump with a defined and constant volume flow. Particles from a certain size clog the screen and thus, the open surface of the screen is decreased. Consequently, the pressure in front of the screen is increasing and determined by a sensor.

Advantages

- Easy and safe handling

- Improved reproducibility by double-chamber hopper

- Little idle times during screen change by cassette system

- Filter change without extruder stop

- Saving of working time due to optionally available double-chamber hopper

Materials

Testing of masterbatches, virgin and recycling materials

Application

- Product development – optimizing colour masterbatches

- Quality monitoring and control

- Incoming inspection and output control of masterbatches, compounds or polymers

Control

Microprocessor control with HMI, function keys and data wheel.

Customers

- Masterbatch manufacturers

- Recycling companies

- Raw material manufacturers

- Compounding and refining companies

- Processing companies

- Universities and institutes