COLLIN Winders are available in different designs. Furthermore, all winders are designed according to the respective web speed. Our Lab Line winders are designed for a winding width of up to 1,000 mm.

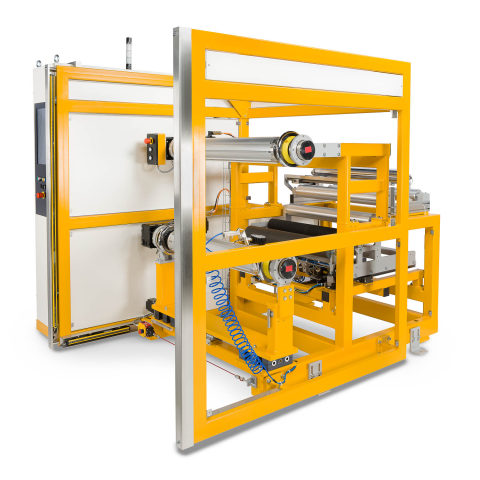

Winder types

- Contact or central winder (with or without roller conveyor)

- Winder, centrally driven, with contact roll

- Winder with contact slide: with this winding unit, there are three possibilities of winding – central winding, contact winding with adjustable pressure and gap winding with adjustable gap (0 – 30 mm).

Advantages

- Bidirectional winding

- High accuracy during gap winding

- High speeds

- Optimal visualisation and control

- Numerous features

- Stand-alone unit

- Large diameters

- High flexibility

- Easy handling

- Upscaling

Winding material

- Flat films, fleece, strands, hoses

- All types of flexible carrier material/metal film

- Woven and non-woven

- Laminated plastic

Application

Pilot productions, product development, small batch production

Customers

- Raw material manufacturers

- Compounding and refining companies

- Processing companies

- Universities and institutes

- Pharmaceutical companies

- Companies in the medical sector